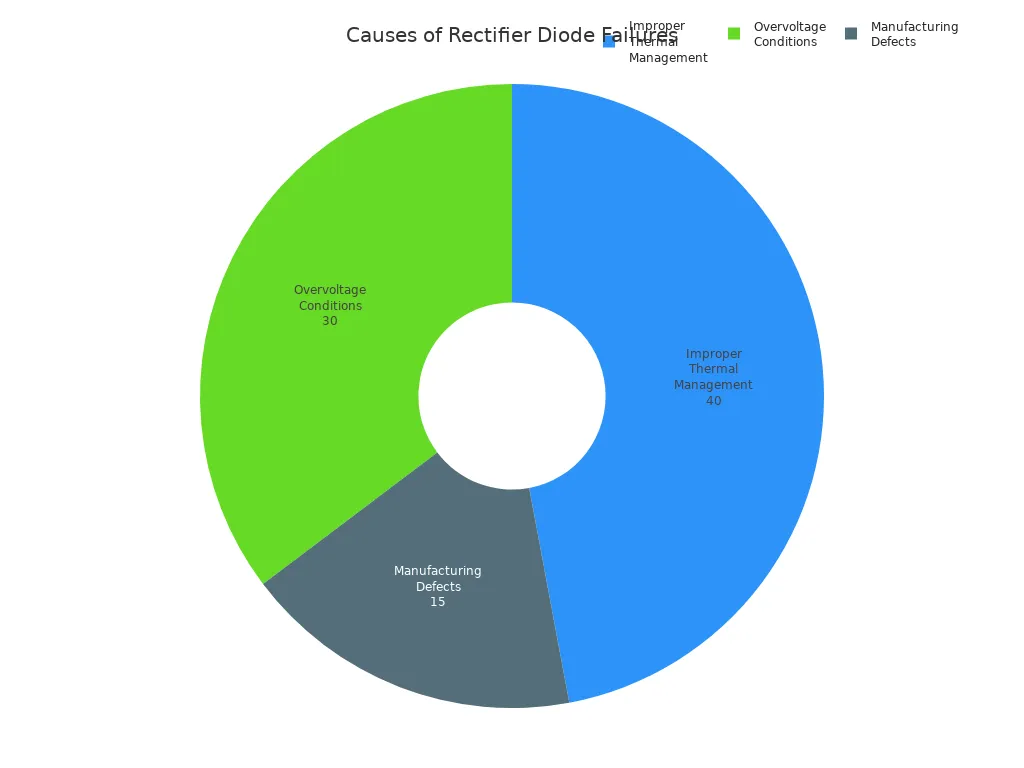

Mengke Electronics uses three smart ways to fix power rectifier diode problems. Their team looks at each broken rectifier diode with careful visual checks. They find the main reason for the problem. They replace or upgrade parts as needed. Experts at Mengke Electronics use top technology and follow strict safety rules. They help users find and fix problems fast. Every solution works well for beginners and professionals. The company cares a lot about quality. Industry data shows that 85% of failures come from overvoltage, heat problems, or defects.

Key Takeaways

-

Looking at the diodes helps find problems, like damage or getting too hot.

-

A multimeter helps test if the diode works well, so it is safe to use.

-

Safety is very important; always turn off the power and follow safety rules before you check the diodes.

-

Checking and taking care of diodes often can stop them from breaking and make circuits last longer.

-

Using better diodes makes things work better and keeps them cooler.

Troubleshoot Power Rectifier Diode: Visual Checks

Signs of a Faulty Rectifier Diode

At Mengke Electronics, technicians look for signs that a rectifier diode is bad. They check if there is any damage, burns, cracks, or rust. These things often mean the rectifier circuit has problems. The team also checks for strange voltage, parts that get too hot, and lights that flicker. These signs show the rectifier might not work right. The table below lists common signs and what they mean:

|

Indicator |

Description |

|---|---|

|

Abnormal Output Voltage |

Strange voltage can mean the rectifier is broken. |

|

Overheating Components |

Too much heat in the rectifier or nearby parts can mean failure. |

|

Flickering Lights or Unstable Performance |

Flickering lights can mean the rectifier circuit is not working well. |

Mengke Electronics uses special tools to find these signs. Their experts know that finding problems early stops bigger failures.

Using a Multimeter for Diode Testing

After looking at the diode, the team uses a multimeter to test it. This tool checks how much resistance the diode has in both directions. Electrical tests are more exact than just looking. The table below shows how good each method is:

|

Method |

Effectiveness in Identifying Faults |

Description |

|---|---|---|

|

Visual Checks |

Moderate |

Can spot damage you can see like cracks or color changes. |

|

Electrical Testing |

High |

Gives detailed results about how the diode works, checking resistance both ways. |

Mengke Electronics suggests using D&V’s test systems for better results. These systems act like real-life situations and help fix diode problems fast. Using a multimeter helps workers know if a diode is good or needs to be changed.

Safety Steps Before Inspection

Safety is very important at Mengke Electronics. Before checking any rectifier diode, workers turn off the power and tag the switch. They look at the electrical plan and see how things are set up. The table below shows key safety rules:

|

Do's |

Don'ts |

|---|---|

|

Learn about danger spots by looking at the plan and layout before fixing anything. |

Turn on the rectifier if you are NOT sure about the steps. |

|

Set the AC disconnect to 'OFF' before you start. |

Start the rectifier at any setting except the lowest. |

|

Tag and lock the switch so no one turns on the power while you work. |

Put too much load on the rectifier. |

|

Check and tighten any loose connections from shipping. |

Add new equipment inside the rectifier without asking the factory. |

|

Make sure the rectifier is at its lowest output before turning it on. |

N/A |

Mengke Electronics teaches workers to follow these steps every time they fix a rectifier diode. Their focus on safety and quality helps circuits work well and keeps customers happy.

Troubleshoot Rectifier Circuit: Root Cause Analysis

Overvoltage and Overcurrent Stress

Technicians at Mengke Electronics know that too much voltage or current can break rectifier circuits. If voltage spikes go past what the diode can handle, it may stop working. Too much current makes the diode get very hot. This can cause the rectifier diode to fail and work badly. In factories, voltage spikes happen a lot. For example, a plastic extrusion company had voltage spikes three times every second. These spikes hurt diodes and made the rectifier break again and again. Most of these problems come from power supply troubles or changes in electricity. The table below lists common causes and what they mean:

|

Cause |

Explanation |

|---|---|

|

Overvoltage |

Voltage goes over the diode’s limit and breaks it. |

|

Overcurrent |

Current gets too high, making the diode hot and weak. |

|

Environmental Factors |

Hot or wet places make diodes age faster. |

|

Electrical Noise |

Fast changes in electricity can hurt diodes in some circuits. |

Mengke Electronics checks for strange output voltage, hot parts, and signs of bad rectifiers step by step. Their experts say to use overvoltage protection and current limiters to stop these problems from happening again.

Circuit Design Flaws

Bad design in the rectifier circuit can make it fail many times. If heat cannot escape, diodes get too hot. Too much current or short circuits can also break the rectifier. If the circuit is not made for the right load or sudden changes, it can cause more diode problems. Mengke Electronics tells engineers to check wires and connections, use good heat sinks, and install everything the right way. Their team looks at every circuit for signs of bad rectifiers and makes sure each diode fits the job.

-

Not enough heat escapes

-

Too much current or short circuits

-

Design mistakes that ignore load and sudden changes

Mengke Electronics gives special fixes to repair broken rectifier circuits and make them work better.

Preventing Repeat Failures

To stop diode failures, you need good design and regular checks. Mengke Electronics suggests these steps:

-

Use the right protection for each rectifier circuit.

-

Follow the rules and put diodes in the right place.

-

Check and fix things often.

-

Test with electricity and look for damage.

-

Use thermal imaging to find hot parts.

Their experts use step-by-step checks to find and fix bad rectifier diodes. By checking wires and connections, they lower the chance of rectifier circuit problems. Mengke Electronics helps customers keep their power rectifier diodes working well and lasting long.

Tip: Regular checks and careful setup help stop rectifier diode problems and keep circuits working right.

www.jymskj.com

Shenzhen JinyiMingsheng Technology Co., Ltd.