Pipe seamless steel is great for hydraulic systems because it is very strong. It can handle high pressure and is very reliable. Engineers use pipe seamless steel when safety is very important. They also use it when good performance is needed. Pipe seamless steel uses high-quality materials. It follows strict rules like DIN 2413. This helps pipe seamless steel work well in hard places. It can also handle high-pressure jobs.

Key Takeaways

-

Seamless steel pipes do not have weld seams. This makes them stronger and safer for high-pressure hydraulic systems. These pipes must meet strict rules like DIN 2413. These rules make sure the pipes have the right size, strength, and quality for hard jobs. Seamless pipes fight rust and corrosion better than welded pipes. They do even better with special coatings. They last longer and can handle pressure changes well. This means there are fewer repairs and less downtime. Many industries use seamless steel pipes for safe and reliable hydraulic systems. These pipes work well even under heavy loads.

Pipe Seamless Steel Overview

What Is Pipe Seamless Steel

Pipe seamless steel is a steel tube with no welded seams. Manufacturers make it by heating a solid steel piece. They pierce the steel to make a hollow tube. They use hot rolling, cold drawing, and hot extrusion. Each way shapes the steel and makes it strong.

-

Hot rolling heats and rolls the steel piece. This way is cheaper for regular uses.

-

Cold drawing pulls the hot steel into a tube. This makes the pipe very exact and gives it thin walls.

-

Hot extrusion pushes the steel through a mold. This makes pipe that can handle high pressure and big flow.

This process removes weak spots found in welded pipes. Seamless pipe is very strong and handles pressure well. It also fights rust better than welded pipe. The smooth surface and exact size make it good for hydraulic systems. New machines and robots help make seamless pipe even better. New metals and smart tools help seamless pipe last longer and work well in hard places.

Note: Seamless pipe can now use new materials and digital checks. This helps it last longer and work better in tough jobs.

How It Differs from Welded Pipe

Seamless pipe and welded pipe look alike but are made differently. They also work differently. The table below shows some main differences:

|

Aspect |

Seamless Pipe |

Welded Pipe |

|---|---|---|

|

Manufacturing Process |

Made from solid billets, pierced and rolled |

Made by rolling and welding steel sheets |

|

Structural Integrity |

No weld seam, stronger and safer |

Contains weld seam, may have weak points |

|

Wall Thickness |

Less consistent |

More precise and consistent |

|

Heat Treatment |

Some types harden during manufacture |

Most types require heat treatment after making |

|

Cost |

More expensive |

More cost-effective |

|

Size Availability |

Limited size range |

Wider range of sizes and shapes |

|

Typical Applications |

High-pressure, critical uses |

General use, less extreme conditions |

Seamless pipe is special because it has no weld seam. This makes it stronger and safer for high pressure and heat. Welded pipe costs less and comes in more sizes. But it may not be as strong as seamless pipe. For hydraulic systems, seamless pipe is often the best pick. It can do hard jobs and last a long time.

Seamless Pipe Standards

DIN 2413 and Other Standards

DIN 2413 is a set of strict rules for seamless pipe. These rules are for pipes used in hydraulic systems. DIN 2413 tells what size and shape the pipe should be. It also says how strong the pipe must be. This helps the pipe work safely with high pressure. Engineers like DIN 2413 because it makes sure pipes are strong. The pipes also fit well in machines.

Companies like TORICH follow DIN 2413 and other rules. Some other rules are ASTM, EN, and JIS. These rules help seamless pipe work for many jobs. TORICH uses smart machines to make pipes. They check each pipe to make sure it is strong. They test pipes to see if they break in cold or high pressure. TORICH has certificates and patents to show their pipes are good.

Note: Pipes that follow DIN 2413 and other rules help stop leaks and breaks in hydraulic systems.

TORICH and other companies do these things for quality:

-

They use smart ways to make pipes very exact.

-

They check and test every seamless pipe.

-

They make special seamless pipe for different jobs.

-

They keep their certificates up to date.

Material Grades and Sizes

Seamless pipe for hydraulic systems comes in many grades. Each grade is good for different jobs. Some common grades are:

-

Medium carbon steel (45#) is stronger and harder.

-

Alloy steels like C15, C20, 20MnV6, and 25CrMo4 last longer and fight rust.

These grades help seamless pipe work in many places.

Seamless pipe comes in many sizes too. The table below shows some sizes for hydraulic systems:

|

Parameter |

Range |

|---|---|

|

Outside Diameter |

|

|

Wall Thickness |

0.028” to 0.120” |

Some seamless pipe can be bigger or thicker for special jobs. TORICH makes seamless pipe from 4 mm to 426 mm wide. They also make pipes from 1 mm to 100 mm thick. This helps engineers pick the right pipe for each job.

Advantages of Seamless Pipe

Strength and Pressure Resistance

Seamless pipe is very strong and can handle high pressure. It is made by piercing a solid steel piece and stretching it into a tube. This way, there are no weak spots like weld seams. Weld seams can make welded pipe weaker. Seamless pipe has the same structure all around. This helps it hold up under heavy loads and high pressure.

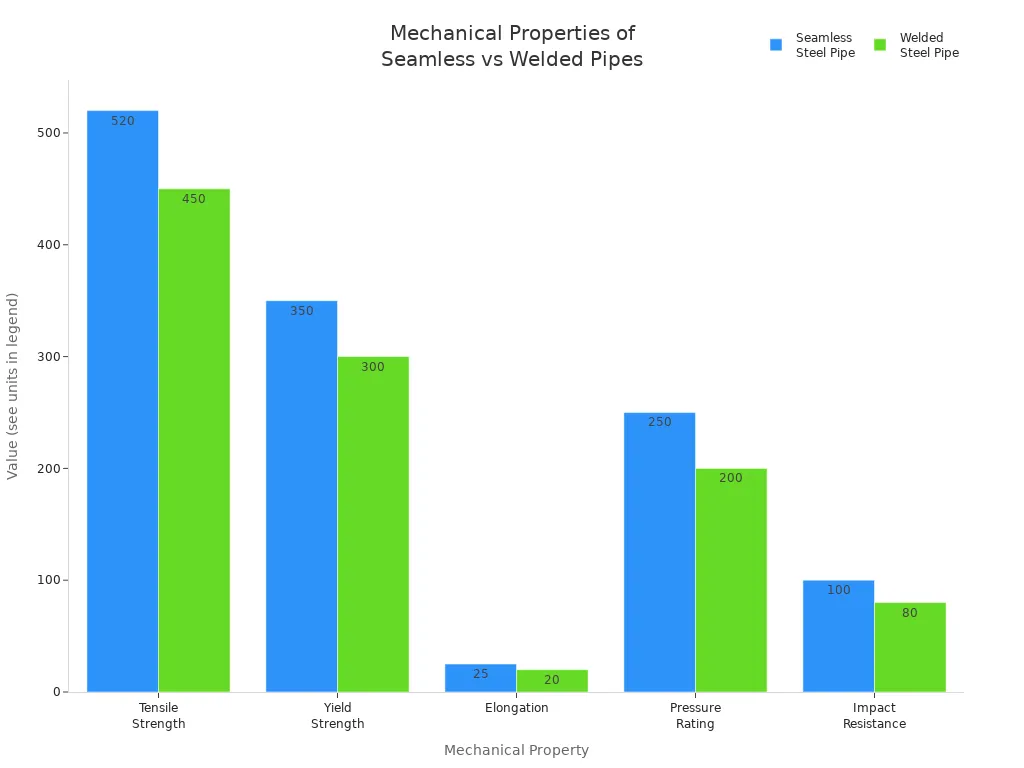

The table below shows how seamless pipe and welded pipe compare:

|

Mechanical Property |

Seamless Steel Pipe |

Welded Steel Pipe |

|---|---|---|

|

Tensile Strength (MPa) |

Approximately 520 |

Approximately 450 |

|

Yield Strength (MPa) |

Approximately 350 |

Approximately 300 |

|

Elongation (%) |

Around 25 |

Around 20 |

|

Pressure Rating (Bar) |

About 250 |

About 200 |

|

Impact Resistance (J) |

Around 100 |

Around 80 |

Seamless pipe is stronger than welded pipe. It can take more force before it breaks or bends. It also has a higher pressure rating. This makes seamless pipe the best for tough hydraulic jobs.

Hydraulic systems need pipes that can handle over 1000 psi. Seamless pipe works well because it does not have weld seams that might break. Engineers use seamless pipe for hard jobs in factories, cars, and machines.

Seamless pipe is also more reliable. Welded pipe can crack at the weld seam. This happens more in high pressure or heat. Seamless pipe does not have this problem. This makes it safer and last longer.

Fatigue and Corrosion Resistance

Hydraulic systems run for a long time and face lots of pressure changes. Seamless pipe can handle many pressure cycles without cracking. Tests show seamless pipe stays strong after many cycles. This makes it good for machines that work every day.

Seamless pipe lasts longer because it does not have weak spots. Engineers test each pipe with special tools. They use hydraulic tests and ultrasonic checks. These tests make sure the pipe is strong and safe.

Corrosion resistance is important because water, oil, and chemicals can hurt steel. Seamless pipe can get special coatings to stop rust and corrosion. Some common coatings are:

|

Surface Treatment Method |

Description and Corrosion Resistance Mechanism |

|---|---|

|

3PE Anti-corrosion Process |

Three layers: epoxy powder, glue, and plastic; makes a strong shield against rust. |