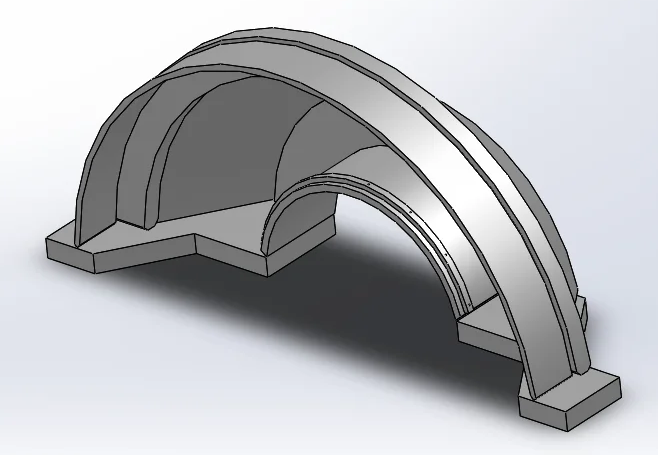

When it comes to hood fabrication, particularly for industrial machinery, special vehicles, and energy equipment, precision and reliability are everything. Whether you’re dealing with protective hoods for engines or structural covers for heavy-duty systems, even the smallest manufacturing issue can result in poor fit, reduced performance, or early failure.

At Hangzhou Hengli Metal Processing Co., Ltd., we understand the complexity of hood processing and offer a full suite of solutions—from flame cutting of plates up to 500mm thick, to CNC machining and ASME IX-certified welding. In this article, we’ll explore five common challenges in hood fabrication—and how to overcome them, based on real-world production insight.

1. Inconsistent Material Thickness and Warping

The challenge:

One of the most frequent problems in hood fabrication is inconsistent plate thickness, especially when using heavy or low-grade materials. Uneven thickness can lead to distortion during cutting or welding, resulting in poor alignment or warping after assembly.

How to overcome it:

At Hengli, we source only high-quality certified materials with controlled tolerances. We use advanced flame and laser cutting systems that minimize heat distortion and ensure smooth edges. Additionally, precision forming techniques allow us to maintain dimensional consistency throughout the hood’s structure.

2. Welding Deformation and Stress Concentration

The challenge:

Welding is critical to hood fabrication—but improper welding techniques can create residual stress, leading to deformation, cracking, or long-term fatigue failure, especially in high-vibration applications like construction or agricultural machinery.

How to overcome it:

Hengli employs ASME IX and TUV (EN287) certified welders who use advanced welding sequences and preheat strategies to control thermal expansion. Robotic welding and custom jigs are used in high-volume projects to ensure accuracy, reduce stress concentration, and improve repeatability.

3. Poor Fitment and Tolerance Misalignment

The challenge:

Even minor inaccuracies in cutting, bending, or hole placement can lead to a hood that doesn’t fit the frame or assembly, causing delays in the production line or on-site installation.

How to overcome it:

Hengli uses CNC machining and precision forming processes to achieve tight tolerances and perfect alignment. All parts undergo dimensional inspection before and after assembly. Our teams collaborate with clients during the design-for-manufacturing (DFM) phase to eliminate risks early in the production cycle.

4. Surface Finish Incompatibility

The challenge:

A hood’s protective role often requires corrosion-resistant coatings, paint, or powder coating. Inconsistent surface preparation or incompatible finishing methods can lead to peeling, rusting, or inconsistent appearance—especially in outdoor applications.

How to overcome it:

Our hood processing services include a variety of finishing options, including painting, powder coating, and anodizing. Before finishing, we ensure the surface is properly cleaned, deburred, and prepped using sandblasting or chemical treatments. The result is a durable and uniform finish that withstands harsh conditions.

5. Limited Flexibility for Custom Requirements

The challenge:

Industrial clients often require hoods in low-to-mid volumes, with specific geometries, access panels, or attachment points. Many suppliers lack the flexibility to adapt their processes quickly to such custom demands.

How to overcome it:

Hengli specializes in custom hood processing, offering full design collaboration, quick prototyping, and flexible fabrication lines. Whether it’s a one-off prototype or a repeat production batch, we adapt our tooling and scheduling to suit customer needs—without compromising lead time or quality.

Conclusion: Partner with a Hood Fabrication Expert to Overcome Every Challenge

From inconsistent material properties to finishing issues and poor fitment, hood fabrication can present a variety of challenges—especially when high performance and longevity are non-negotiable.

At Hangzhou Hengli Metal Processing Co., Ltd., we leverage advanced cutting technologies, certified welding practices, and strict quality control to overcome these challenges. Whether you're in the construction equipment, energy, agriculture, or specialty vehicle sector, our tailored hood processing services are designed to deliver high-value, high-precision results.

By choosing a partner with deep technical expertise and flexible capabilities, you not only avoid costly production errors—you gain a competitive edge in your market.

Need a reliable hood processing partner? Contact Hengli today and get the performance your equipment deserves.

www.hlmetal.net

HENGLI