In modern industrial power transmission systems, efficiency, reliability, and adaptability are key factors influencing operational success. The air-cooled adjustable speed permanent magnetic coupling is an advanced technology designed to provide seamless torque transmission while allowing speed adjustments and reducing mechanical wear. With its non-contact power transfer mechanism, air cooling capabilities, and speed modulation features, this coupling plays a significant role in optimizing industrial processes across various sectors.

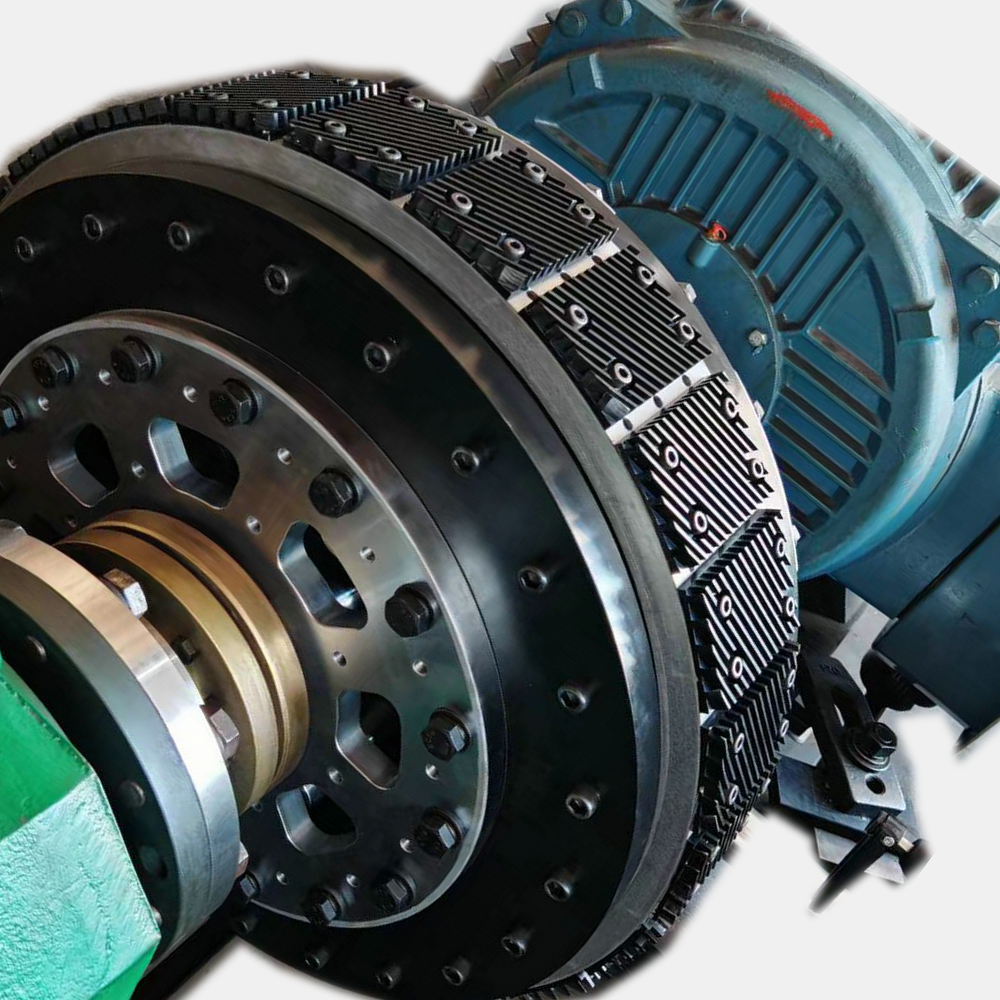

Air-Cooled Adjustable Speed Permanent Magnetic Coupling

An air-cooled adjustable speed permanent magnetic coupling is a non-contact mechanical coupling that uses the principles of magnetic field interaction to transfer torque between an input and output shaft. Unlike traditional mechanical couplings that rely on physical connections such as gears or belts, this type of coupling operates through permanent magnets and eddy currents to achieve smooth and controlled power transmission.

The adjustable speed function is achieved by varying the magnetic interaction between the rotating elements, allowing for precise speed control without direct mechanical engagement. The air-cooled design ensures efficient heat dissipation, reducing the need for additional cooling mechanisms like liquid cooling systems, thus enhancing operational efficiency and lowering maintenance requirements.

Role and Significance in Industrial Power Transmission Systems

Air-cooled adjustable speed permanent magnetic couplings have gained significant importance in industrial applications due to their ability to enhance system efficiency, reliability, and energy savings. Their key roles include:

1. Energy Efficiency and Speed Regulation

-

Traditional mechanical couplings often lead to energy losses due to friction and mechanical resistance. Air-cooled adjustable speed permanent magnetic couplings, on the other hand, enable precise speed control by adjusting the magnetic field, allowing systems to operate at optimal speeds based on load requirements.

-

This feature is particularly beneficial in applications such as pumps, fans, and conveyor systems, where speed adjustments directly impact energy consumption.

2. Reduced Mechanical Wear and Maintenance

-

Since the transmission of torque occurs without direct contact, there is minimal mechanical wear, significantly extending the lifespan of machinery components.

-

Unlike conventional couplings that require frequent lubrication and replacement due to wear and tear, air-cooled adjustable speed permanent magnetic coupling systems require minimal maintenance, leading to reduced downtime and lower operational costs.

3. Overload Protection and System Safety

-

One of the major advantages of permanent magnetic couplings is their inherent overload protection capability.

-

In cases of sudden load fluctuations or system faults, the magnetic coupling allows for controlled slippage, preventing excessive torque transmission and protecting the connected machinery from potential damage.

4. Improved Operational Flexibility and Adaptability

-

Air-cooled adjustable speed permanent magnetic couplings are suitable for various industrial environments, including applications requiring variable speed control without the complexity of electronic variable frequency drives.

-

They provide a simpler, more robust alternative to variable frequency drives in environments where electromagnetic interference is a concern.

Key Technological Features of Air-Cooled Adjustable Speed Permanent Magnetic Coupling

The design and functionality of air-cooled adjustable speed permanent magnetic couplings are based on a combination of advanced magnetic coupling principles, air-cooling mechanisms, and adjustable speed control technologies. The following are its defining technological features:

1. Permanent Magnetic Torque Transmission

-

The coupling utilizes high-strength rare-earth magnets (such as Neodymium-Iron-Boron) to create a powerful and stable magnetic field for torque transfer.

-

Torque is transmitted via eddy currents induced in the conductor disc, allowing for efficient and smooth power transmission.

2. Adjustable Speed Control Mechanism

-

The output speed of the coupling can be varied by adjusting the distance between the magnet rotor and the conductor rotor.

-

Some advanced models use electronic actuators to dynamically control this distance, enabling precise real-time speed adjustments.

3. Air-Cooled Heat Dissipation System

-

Unlike liquid-cooled systems that require complex piping and additional maintenance, air-cooled adjustable speed permanent magnetic couplings employ air-cooled heat dissipation mechanisms using radiator fins, ventilation ducts, or passive airflow designs.

-

This air-cooled design improves thermal stability, ensuring efficient operation even under high load conditions.

4. Non-Contact Operation and Wear-Free Design

-

The absence of physical contact between rotating elements eliminates issues related to mechanical friction, lubrication, and component degradation.

-

This significantly extends the operational life of the coupling while maintaining high performance over time.

5. Compact and Modular Design for Easy Integration

-

Air-cooled adjustable speed permanent magnetic couplings are typically designed to be compact and modular, allowing for easy integration into existing drive systems without major modifications.

-

Their adaptability makes them suitable for a wide range of industrial applications, from HVAC systems to heavy-duty mining conveyors.

The air-cooled adjustable speed permanent magnetic coupling represents a significant advancement in industrial power transmission by offering non-contact torque transfer, energy-efficient speed control, and reliable overload protection. Its air-cooled heat dissipation and adjustable speed capabilities make it an ideal choice for industries seeking efficient, low-maintenance, and high-performance drive solutions.

As industries continue to prioritize energy efficiency, operational reliability, and cost savings, air-cooled adjustable speed permanent magnetic coupling technology is poised to play an increasingly important role in modernizing drive systems across various sectors, from manufacturing and mining to HVAC and water treatment facilities.

By integrating advanced permanent magnet materials, innovative cooling designs, and intelligent speed control mechanisms, air-cooled adjustable speed permanent magnetic couplings will continue to shape the future of industrial power transmission systems.

www.magicmag-tech.com

SHANGHAI GAOLV E&M Technology Co.,Ltd.