In modern electrical infrastructure, effective grounding systems are fundamental to safety and operational reliability. Ensuring secure, corrosion-resistant, and permanent connections between grounding conductors and electrodes has become an industry priority. Among various grounding methods, exothermic welding for grounding has emerged as the superior technology, offering unparalleled performance and reliability. Sunlightweld, a leading innovator in this field, has elevated the standards of exothermic welding for grounding, introducing patented technologies, certified reliability, and unmatched user-friendly features.

Introduction to the Exothermic Welding for Grounding

Exothermic welding for grounding—also known as exothermic bonding—is a chemical welding process that creates permanent molecular bonds between copper conductors. This method employs a controlled reaction between copper oxide and aluminum powder, generating molten copper that fuses metals at extremely high temperatures. Unlike traditional mechanical connectors, exothermic welding ensures permanent electrical continuity, high corrosion resistance, and exceptional durability even under harsh environmental conditions. These attributes make it especially suited for critical grounding applications such as substations, airports, renewable energy facilities, and telecommunications systems.

Sunlightweld has perfected the art of exothermic welding for grounding by investing extensively in research, innovation, and product development. Its solution provides permanent, low-resistance electrical connections that consistently outperform conventional grounding methods, delivering unmatched reliability and performance.

Why Choose Sunlightweld Exothermic Welding for Grounding

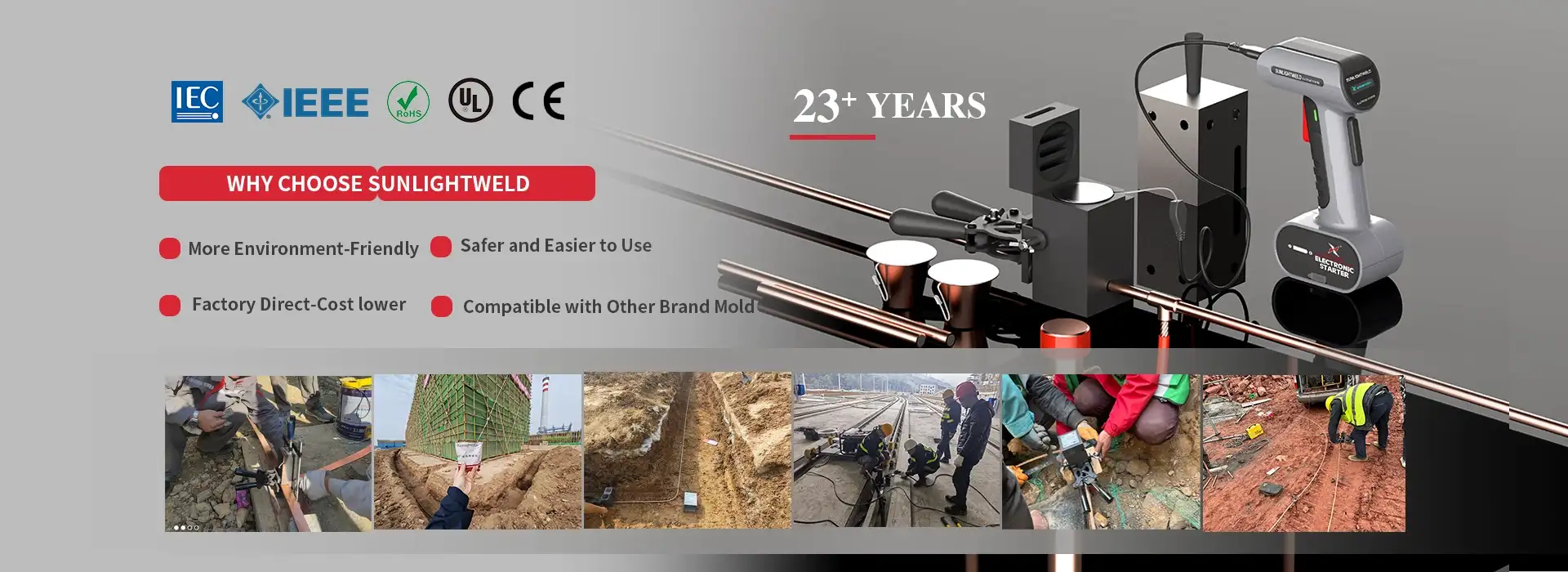

Exothermic welding for grounding is indispensable for achieving secure, durable, and reliable electrical connections across numerous industries. Among various exothermic welding for grounding solutions available today, Sunlightweld eco-friendly electronic ignition exothermic welding uniquely excels, combining advanced technology, rigorous certifications, cost-effectiveness, and environmentally friendly practices.

Globally Recognized Certifications and Patented Technology

Sunlightweld exothermic welding for grounding proudly holds internationally renowned certifications, including IEEE837, UL467, IEC62561-1, CE, and RoHS. The IEEE837 and UL467 certifications are particularly significant, verifying Sunlightweld's compliance with stringent safety and quality standards, ensuring widespread acceptance in critical markets such as the United States. Additionally, Sunlightweld has secured American patents for its innovative exothermic welding for grounding technology, highlighting its valuable contributions to the industry.

The exothermic welding for grounding joints produced by Sunlightweld are consistently robust, smooth, attractive, and entirely free of pores or defects. This superior welding quality significantly surpasses competitors, offering better electrical conductivity, enhanced corrosion resistance, and extended product lifespan.

EPLUS Electronic Ignition: Safer, Smarter, and Environmentally Friendly

Sunlightweld's innovative EPLUS electronic ignition system significantly enhances exothermic welding for grounding by offering remarkable advancements in environmental sustainability, user-friendliness, and operational safety. Featuring convenient USB Type-C charging, the EPLUS ignition system is not only eco-friendly but also simple and safe to operate, requiring minimal training to achieve professional-quality exothermic welding for grounding outcomes.

The EPLUS ignition starter offers exceptional resilience with IPX3 waterproofing and robust shock resistance, making it ideal for rugged industrial environments and outdoor conditions. Unlike many competitors, Sunlightweld's ignition system reliably performs exothermic welding for grounding operations at temperatures as low as -10°C, significantly extending usability under harsh conditions.

Enhanced Efficiency and Profitability

Sunlightweld's EPLUS system revolutionizes the efficiency of exothermic welding for grounding. The ignition process occurs within seconds, dramatically reducing traditional welding operation times by around 70%. Users merely need to place the EPLUS welding cup into the graphite mold, connect the ignition wire, and press the start button—no additional unpacking, preparation, or separate ignition powder handling required. This streamlined process significantly reduces labor costs and increases productivity in exothermic welding for grounding applications.

Moreover, Sunlightweld's direct-from-manufacturer pricing leverages China's robust industrial and supply chain advantages, resulting in highly competitive pricing. International customers consistently report a minimum of 30% higher profit margins compared to competitor products, enhancing profitability for global distributors and partners involved in exothermic welding for grounding solutions.

Unmatched Safety Features

Safety remains at the core of Sunlightweld's exothermic welding for grounding design philosophy. The EPLUS ignition starter incorporates dual switches and warning indicators to minimize operational hazards. An extended 1.8m (optionally 3m) ignition cable enables remote ignition, significantly reducing risks of burns or accidents during exothermic welding for grounding reactions.

Eco-Friendly and Economical

Sunlightweld EPLUS welding cups are uniquely designed for exothermic welding for grounding applications, consumed entirely during the welding reaction, eliminating residue and ensuring minimal environmental impact. Additionally, the welding materials are free from flammable or explosive substances, allowing safe air transport and convenient storage. Protected by eight-layer moisture and shock-resistant packaging, Sunlightweld ensures product stability in diverse environmental conditions, ideal for exothermic welding for grounding.

Compatibility and Partnership Development

Sunlightweld molds and ignition systems for exothermic welding for grounding are fully compatible with other leading industry brands, facilitating easy integration and seamless transitions. Furthermore, Sunlightweld guarantees a consistent 100% ignition rate, offering reliability and performance stability unmatched by competitors in the exothermic welding for grounding market.

Sunlightweld actively seeks global partnerships, offering extensive support through training, technical guidance, and strategic marketing initiatives. The company encourages international partners to participate in virtual factory tours, ensuring transparency, trust, and shared growth opportunities in the expanding exothermic welding for grounding industry.

Sunlightweld exothermic welding for grounding offers cutting-edge technology, globally recognized certifications like IEEE837 and UL467, American patented innovation, unmatched quality, and advanced safety features. Its environmentally friendly EPLUS ignition system significantly enhances operational efficiency and profitability, setting new standards in exothermic welding for grounding solutions worldwide. Sunlightweld continues to foster global collaboration, leveraging China's robust manufacturing capabilities to provide partners with a distinct competitive advantage in exothermic welding for grounding.

https://www.sltup.com/Exothermic-Welding

https://www.sltup.com/Electronic-Ignition-Exothermic-Welding-Wholesale-And-Factory-Price.html

www.sltup.com

Sunlightweld