Zhejiang Petrochemical Co., Ltd. (ZPC), one of China's largest and most advanced integrated refining and chemical enterprises, is known for its high production capacity and stringent operational standards. Recently, ZPC encountered a critical on-site maintenance challenge within its heat exchanger system—a core component in chemical processing under extreme temperature and pressure conditions.

Industry Background and On-Site Challenge

In the chemical and heat exchanger industries, flange sealing surfaces are subjected to long-term exposure to high temperatures, high pressures, and corrosive media. This harsh environment frequently leads to sealing failures, which pose serious risks to both production safety and operational efficiency.

ZPC faced this exact challenge. A critical heat exchanger flange exhibited significant wear and surface distortion, threatening both leakage integrity and continued serviceability. The customer urgently needed a reliable, portable machining solution to restore the sealing surface to industry reusability standards.

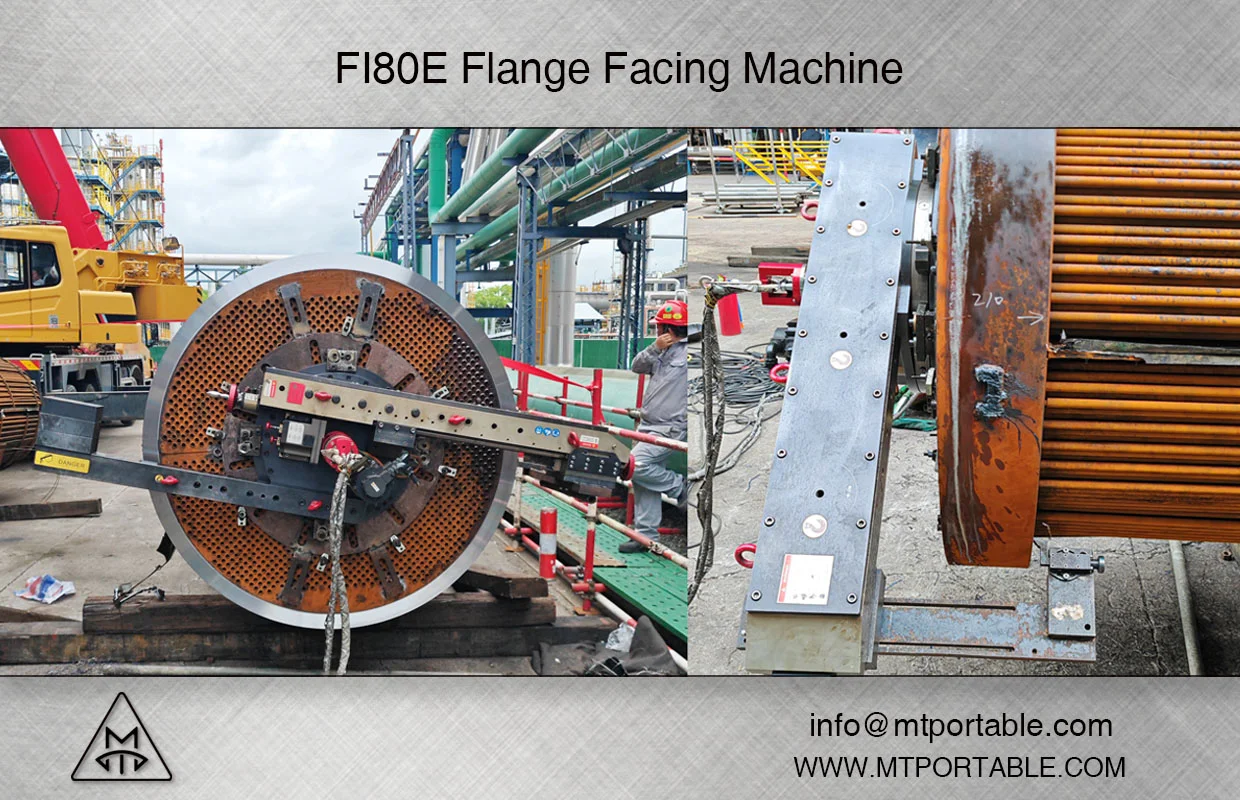

Application of the FI80E Flange Facing Machine

To address the issue, ZPC deployed the FI80E Flange Facing Machine from MT Portable Machine. Renowned for its precision and reliability, the FI80E offers high-performance on-site flange machining capabilities. Its modular design and flexible structure allow for easy adaptation and functional expansion to suit various working conditions.

ZPC technicians performed a critical modification by installing the optional Back Facing Kit, extending the machine's capabilities to repair both the front and back sealing faces of the heat exchanger. This functional versatility proved vital. The FI80E efficiently machined the damaged surfaces, restored the sealing interface flatness and smoothness, and met strict industry reusability standards—all without requiring equipment removal or off-site processing.

Equipment Performance and Brand Value

Throughout the operation, the FI80E flange facer demonstrated outstanding machining stability, superior surface finish, and precise control—all key attributes of MT Portable Machine’s engineering excellence. This case further reinforces MT Portable Machine as a leading manufacturer of high-quality, field-proven on-site machining solutions.

Conclusion

By using the FI80E, Zhejiang Petrochemical successfully mitigated a major operational risk, ensuring both plant safety and production continuity. The case highlights the exceptional adaptability and effectiveness of MT Portable Machine’s solutions in the demanding chemical and heat exchanger industries.

If you are facing similar challenges in on-site flange machining, contact the MT Portable Machine technical team for the latest product specifications and customized machining solutions at info@mtportable.com

www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd