Industrial boilers are the backbone of many heavy industries, including power generation, cement production, metallurgy, and chemical processing. One of the key factors affecting boiler efficiency and fuel utilization is the performance of the chain grating machine grate plate. These components play a critical role in ensuring stable fuel combustion, optimal airflow, and consistent heat output. Understanding how grate plates contribute to combustion efficiency can help plant operators, engineers, and procurement teams make informed decisions about equipment maintenance and upgrades.

The Role of Grate Plates in Chain Grating Boilers

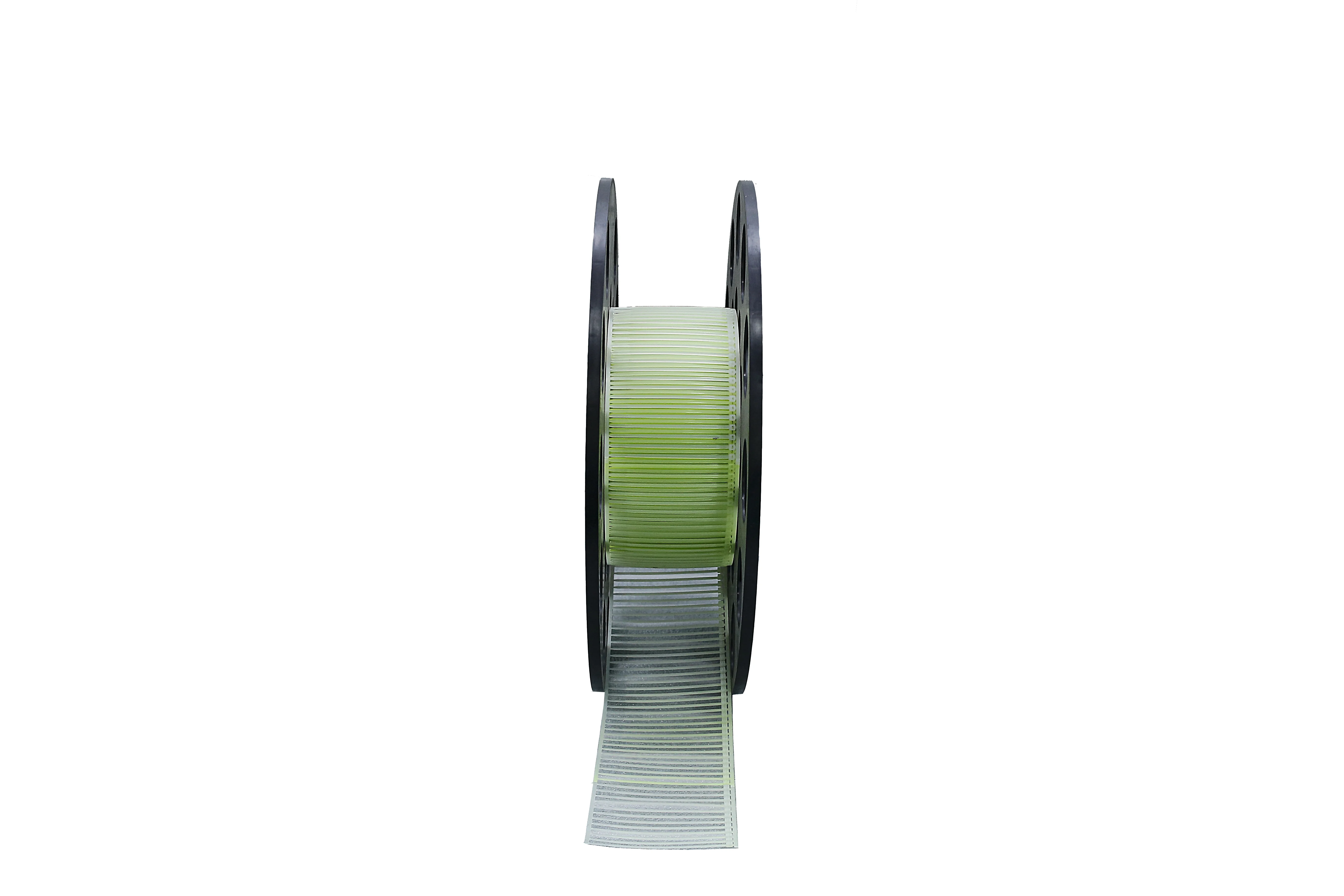

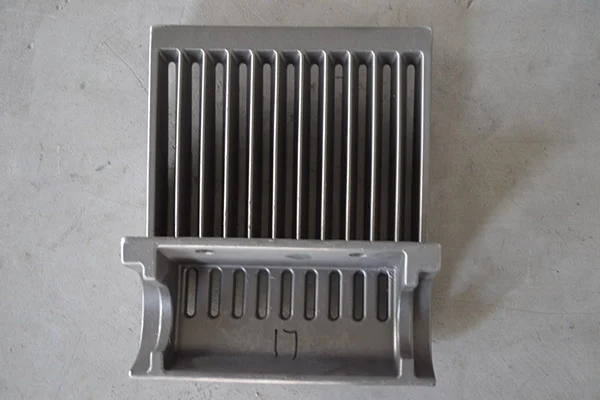

Chain grating machine grate plates form the moving surface of the boiler’s fuel bed. They support solid fuel—such as coal, biomass, or industrial waste—during the entire combustion process. The continuous movement of the grate ensures that fuel passes through multiple combustion zones: drying, ignition, intense burning, and burnout.

By maintaining a controlled and uniform fuel layer, grate plates prevent clumping and uneven burning. This results in more complete combustion, lower unburned fuel residues, and higher overall thermal efficiency for the boiler.

Enhancing Airflow for Optimal Combustion

One of the most critical functions of grate plates is facilitating proper airflow. Grate openings allow primary air to pass upward through the fuel bed, providing the oxygen needed for efficient combustion. Uniform airflow distribution reduces cold spots and prevents incomplete combustion, which can cause excessive smoke, higher fuel consumption, and soot accumulation.

Additionally, the grate’s surface geometry helps evenly distribute fuel and ash. This ensures that ash falls naturally into the ash pit while fresh fuel continuously moves forward, supporting stable and efficient burning.

Material Selection and Durability

High-quality materials are essential for grate plates to perform reliably under the extreme conditions of industrial boilers. Grate plates are exposed to high temperatures, mechanical stress, and abrasive fuel particles. Plates made from low-quality steel or improperly cast materials may deform, crack, or wear quickly, negatively impacting combustion efficiency and requiring frequent replacements.

China Special Metal Group Limited (CSM) is a professional supplier of cast steel components serving industries such as metallurgical machinery, cement and mining equipment, building materials machinery, ceramics, forging, shipbuilding, and chemical processing. With expertise in high-quality cast steel, precision machining, and welded products, CSM produces grate plates that withstand harsh industrial environments while maintaining consistent performance.

Optimized Grate Design for Efficiency

Modern chain grating grate plates are designed with features that enhance combustion efficiency:

-

Uniform Surface and Opening Distribution: Ensures consistent airflow and prevents uneven fuel burning.

-

Wear-Resistant Materials: Extends the service life and maintains performance over thousands of operating hours.

-

Precise Manufacturing: Allows smooth movement of grate chains and reduces mechanical friction, minimizing downtime.

These design considerations not only improve fuel utilization but also contribute to lower maintenance costs and longer intervals between replacements.

Benefits for Industrial Boilers

Well-designed and durable chain grating machine grate plates provide multiple operational benefits:

-

Higher Combustion Efficiency: Complete fuel burnout reduces waste and lowers fuel costs.

-

Stable Heat Output: Uniform fuel burning ensures predictable thermal performance.

-

Reduced Maintenance: Durable materials and precise engineering minimize wear and extend the life of both grate plates and chains.

-

Environmental Compliance: Efficient combustion reduces smoke, particulate emissions, and unburned fuel residues.

Conclusion

Chain grating machine grate plates are essential components that directly influence combustion efficiency in industrial boilers. By supporting uniform fuel distribution, enabling optimal airflow, and withstanding harsh operating conditions, high-quality grate plates help maximize thermal performance and minimize operating costs.

Suppliers such as China Special Metal Group Limited (CSM) play a vital role in delivering durable, precision-engineered cast steel grate plates suitable for a wide range of industrial applications. Investing in reliable grate plates ensures that industrial boilers operate efficiently, safely, and sustainably, providing long-term benefits for plants and operators alike.

www.special-metal.com

China Special Metal Group Limited (CSM)