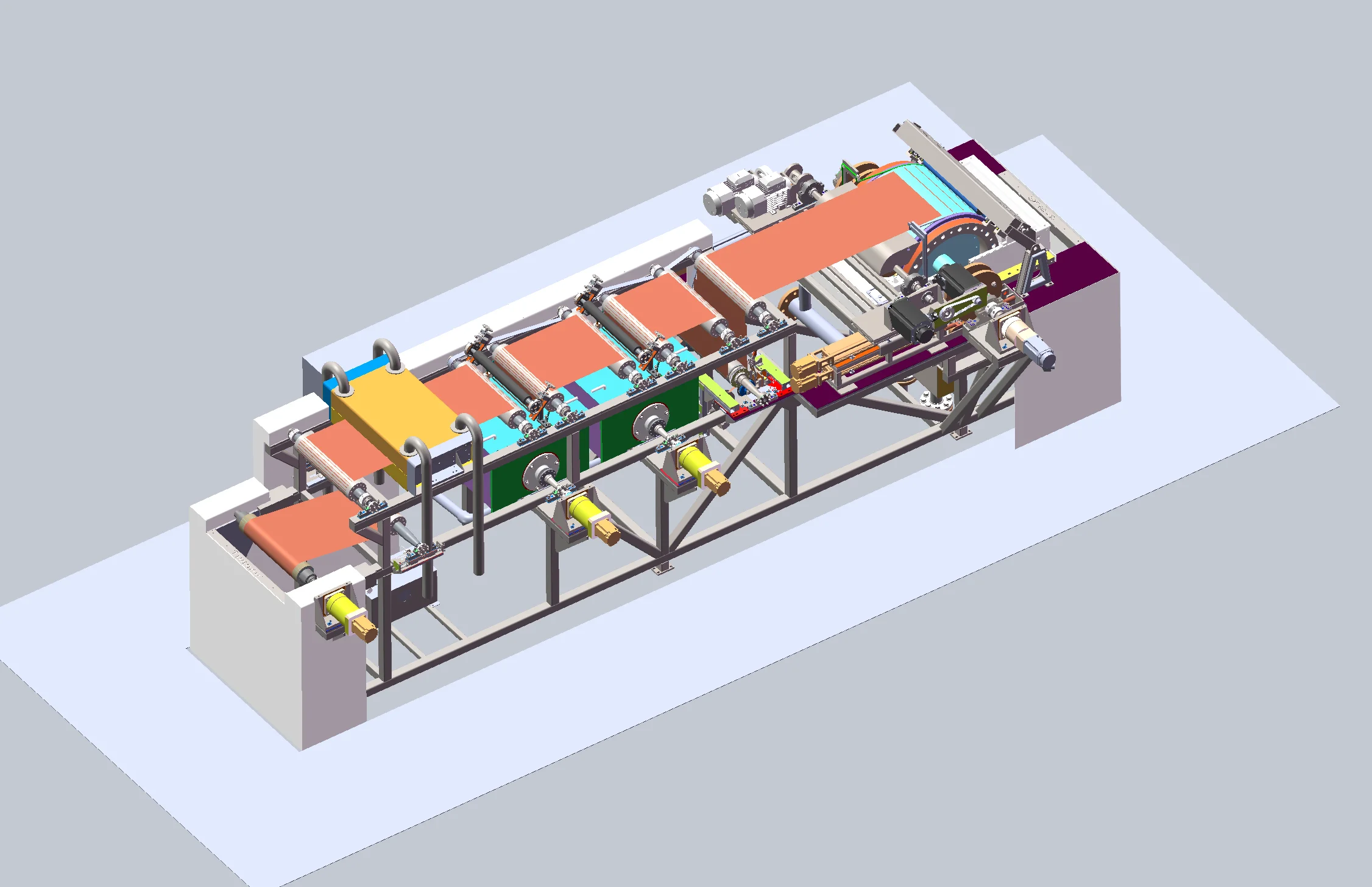

Electrolytic copper foil is a critical material powering today’s clean-energy revolution. From lithium-ion batteries in electric vehicles to advanced electronics, high-quality ultra-thin copper foil ensures excellent conductivity, mechanical strength, and reliability. But how is such precision copper foil produced—and how does a test line help optimize that process?

In this article, we break down the working principles of an electrolytic copper foil test line, step by step, and explore how companies like Timonic are driving innovation in next-generation lithium battery material equipment.

What Is an Electrolytic Copper Foil Test Line?

A test line is a miniature or modular production line used for R&D, formula validation, and process optimization. Instead of full-scale output, it focuses on:

Testing electrolyte formulations

Evaluating current density and deposition rates

Experimenting with foil thickness and surface treatments

Developing new foils for different battery specifications

It enables rapid iteration—lower cost, less risk, and accurate reproduction of industrial production.

The Working Process: From Electrolyte to Foil

The electrolytic production process mainly relies on electrochemical deposition. Here’s how a test line typically works:

1. Electrolyte Preparation

Copper sulfate, sulfuric acid, stabilizers, and additive agents are mixed to create a precisely controlled solution.

Key Goals:

-

High copper ion purity

-

Proper viscosity and temperature

-

Stable chemical composition

Electrolyte quality directly affects foil surface smoothness, grain size uniformity, and tensile strength.

2. Cathode Drum Deposition

A titanium cathode roller rotates inside the electrolyte bath. When DC power is applied:

Copper ions in solution → reduced and deposited → onto the rotating drum

Parameters that must be tuned:

-

Current density

-

Roller speed

-

Electrolyte circulation and filtration

-

Temperature balance

These affect final foil thickness—down to single-digit microns for lithium-battery grade applications.

3. Stripping Ultra-Thin Foil from the Drum

Once a uniform layer forms, the copper foil is peeled smoothly from the roller surface, becoming a continuous sheet.

Here the test line ensures:

-

Stable adhesion force

-

No tearing or wrinkles

-

Thickness consistency across the width

4. Surface Treatments

To meet battery requirements, multiple functional coatings may be applied:

| Coating | Purpose |

|---|---|

| Nodular coating | Improves bonding with electrode materials |

| Anti-oxidation layer | Extends storage life and safety |

| Roughness control | Enhances charge/discharge performance |

A high-precision test line can experiment with different formulations for different battery chemistries.

Drying, Rolling, and Final Inspection

Finally, the foil is dried, slit, tension-rolled, and wound into reels. Quality checks include:

-

Thickness uniformity

-

Conductivity and tensile strength

-

Roughness and grain structure

-

Pinholes or defects

Every micron—and every detail—matters.

Why Test Lines Matter for the Future of Batteries

As EVs demand faster charging, higher energy density, and thinner foils (<4 μm), advanced R&D equipment becomes essential.

Electrolytic copper foil test lines accelerate:

-

New electrolyte additives development

-

Lightweight and high-strength foil technology

-

Green and energy-efficient manufacturing

They are the bridge between laboratory innovation and mass-production success.

Timonic: Innovating Copper Foil Production Technology

Timonic is a professional developer and manufacturer of new-energy lithium battery material equipment, including:

-

Electrolytic copper foil production lines

-

Advanced cathode rollers

-

Customized test line equipment for R&D labs and pilot plants

With strong design capability and engineering experience, Timonic helps global battery material producers improve:

Foil quality & consistency

Production efficiency & automation

Sustainable manufacturing at industrial scale

Whether developing next-generation ultra-thin foils or expanding production capacity, Timonic provides tailored, high-performance solutions.

Final Thoughts

Electrolytic copper foil may look incredibly thin—but behind it lies deep electrochemistry, precision engineering, and relentless innovation. A copper foil test line is where new technology is born: optimizing materials that power smarter grids, greener transportation, and a cleaner world.

If you’re interested in R&D equipment for lithium battery materials or want to learn more about copper foil production technology, Timonic is ready to support your innovation journey.

www.timonic.com.cn

Timonic (Suzhou) Technology Co., Ltd