When it comes to heat-resistant and insulating materials, aluminum tape stands out as a versatile and reliable solution. Widely used in HVAC systems, electronics, automotive components, and industrial repair, aluminum tape offers thermal conductivity, flame resistance, and strong adhesion—making it ideal for both professional and DIY applications.

However, with so many varieties on the market, how do you choose the right aluminum tape for your specific needs? This guide walks you through the key factors to consider and highlights how Dongguan Xuanjie Electronic Products Co., Ltd. delivers high-performance adhesive solutions tailored for modern industries.

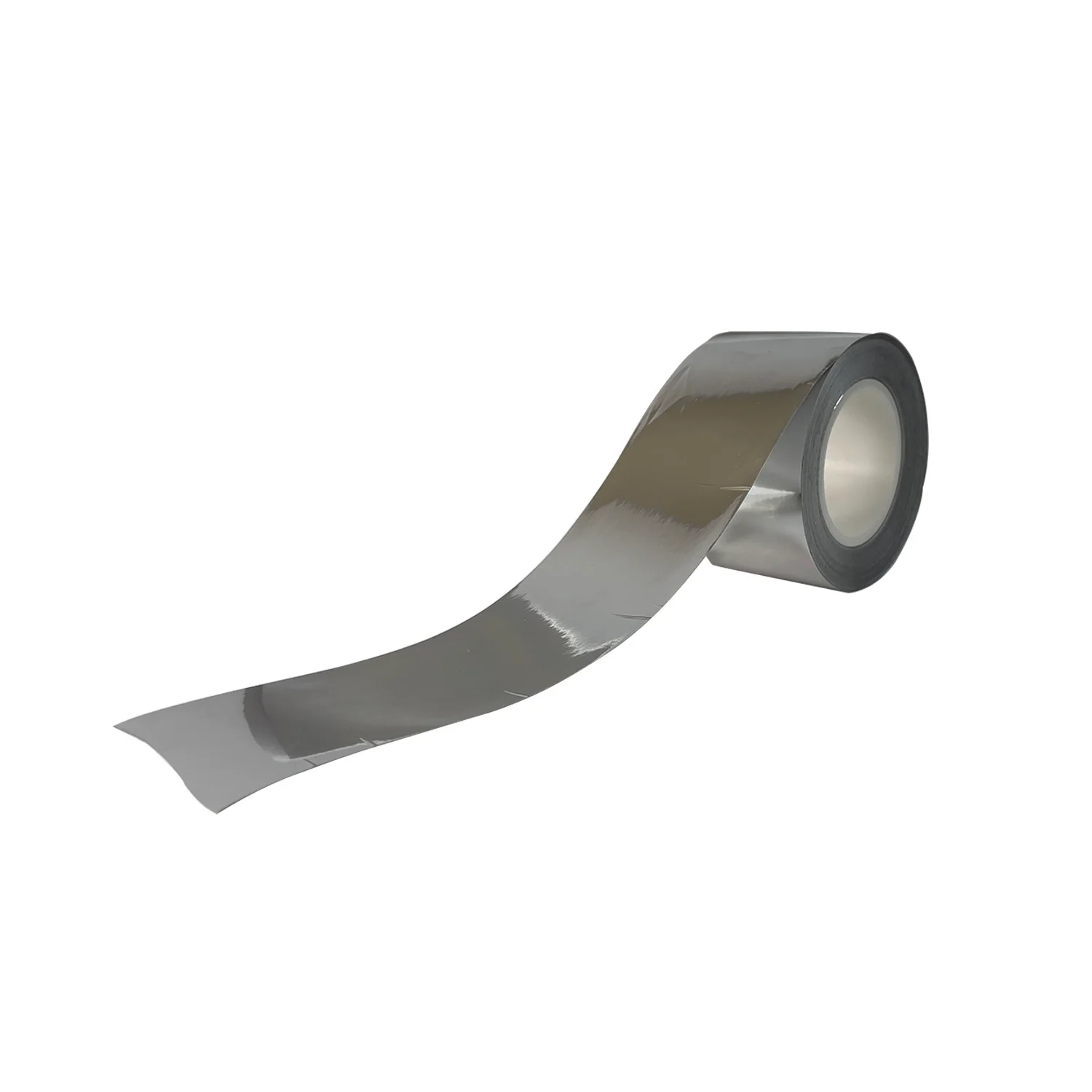

What Is Aluminum Tape?

Aluminum tape, also known as aluminum foil tape, is typically composed of an aluminum backing with an adhesive layer, offering heat reflectivity, durability, and sealing performance. It is commonly used for:

-

Thermal insulation

-

Sealing duct joints

-

Shielding electronics

-

Repairing damaged insulation or wiring

The choice of adhesive and backing thickness can greatly affect performance, especially in environments exposed to high temperatures or electrical interference.

Key Factors to Consider When Choosing Aluminum Tape

1. Heat Resistance Level

Look for aluminum tape that can withstand the maximum temperature range of your application. Some tapes are designed for up to 150°C, while industrial-grade versions may resist temperatures exceeding 300°C. This is essential for automotive engines, high-heat wiring, or industrial furnaces.

2. Adhesive Type

The adhesive used plays a major role in bonding strength and reliability:

-

Acrylic adhesives offer long-term durability and UV resistance.

-

Rubber adhesives provide quick tack and flexibility but may degrade under high heat.

-

Silicone adhesives are ideal for extreme temperatures and electrical insulation.

Dongguan Xuanjie Electronic Products Co., Ltd. uses high-performance adhesives that meet rigorous testing standards for temperature resistance, bonding stability, and application flexibility.

3. Backing Thickness

Thicker aluminum foil provides better heat reflection and mechanical strength, while thinner foil offers more flexibility for wrapping uneven surfaces. Choose based on whether your focus is shielding, patching, or wrapping.

4. Application Surface and Environment

Consider the type of surface the tape will be applied to (metal, plastic, fabric, etc.) and whether it will be exposed to moisture, chemicals, or vibration. Make sure the tape is rated for moisture resistance and corrosion protection if used in harsh environments.

5. Certifications and Compliance

Look for products that meet RoHS, UL, or REACH compliance, especially for use in electronics, aerospace, or regulated industries.

Why Choose Dongguan Xuanjie Electronic Products Co., Ltd.?

With a strong focus on specialty adhesive materials, Dongguan Xuanjie Electronic Products Co., Ltd. stands out as a reliable manufacturer of high-quality tapes for electronic and electrical applications.

Key advantages include:

-

Expertise in R&D: Specialized in black double-sided tape, black-and-white double-sided tape, aluminum repair tape, and other custom adhesive solutions.

-

Advanced production facilities: Equipped with fully automated production lines and compliance-grade testing instruments, ensuring consistent quality and fast delivery.

-

Custom solutions: Able to meet diverse client needs, from prototype development to bulk manufacturing.

-

Stringent quality control: Every batch is tested for adhesion, thermal resistance, tensile strength, and durability.

Whether you're working on consumer electronics, industrial insulation, or repair applications, Xuanjie offers tailor-made aluminum tape solutions that deliver both performance and reliability.

Typical Applications of Aluminum Tape

-

HVAC duct sealing and insulation

-

Shielding cables from electromagnetic interference (EMI)

-

Battery pack heat insulation

-

Repairing punctured insulation layers

-

Protecting sensitive components from radiant heat

Final Thoughts

Choosing the right aluminum tape for heat resistance and insulation isn’t just about sticking power—it’s about ensuring long-term thermal protection, safety, and application-specific performance. From adhesive type to backing material, every detail matters.

If you need a trusted partner for high-performance adhesive solutions, Dongguan Xuanjie Electronic Products Co., Ltd. combines innovation, precision manufacturing, and a commitment to quality to meet the evolving needs of today’s industries.

www.dgxjdz.cn

Dongguan Xuanjie Electronic Products Co., Ltd.