Mechanical seals are an essential component in many industrial applications, including pumps, compressors, and mixers. They prevent the leakage of fluids and gases from the equipment, ensuring safe and efficient operation. Tandem mechanical seals are a popular type of mechanical seal used in high-pressure applications. In this article, we will explore what tandem mechanical seals are, how they work, and their advantages over other types of mechanical seals.

What is Tandem Mechanical Seal?

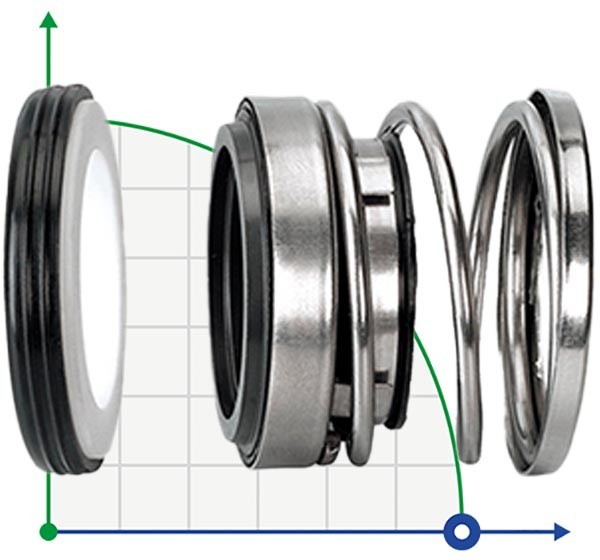

A tandem mechanical seal is a type of mechanical seal that consists of two sets of sealing faces arranged in series. The first set of sealing faces is exposed to the process fluid, while the second set is exposed to a buffer fluid. The buffer fluid is used to cool and lubricate the seal faces, reducing wear and extending the life of the seal. The use of two sets of sealing faces provides an additional level of protection against leakage, making tandem mechanical seals ideal for high-pressure applications.

How Does Tandem Mechanical Seal Work?

Tandem mechanical seals work by creating a barrier between the process fluid and the environment. The first set of sealing faces, which is exposed to the process fluid, creates a primary seal. The second set of sealing faces, which is exposed to the buffer fluid, creates a secondary seal. The buffer fluid is circulated through the seal to remove heat generated by friction between the sealing faces. The use of a buffer fluid also helps to prevent the process fluid from entering the environment in the event of a primary seal failure.

Advantages of Tandem Mechanical Seal:

Tandem mechanical seals offer several advantages over other types of mechanical seals. Firstly, they provide an additional level of protection against leakage, making them ideal for high-pressure applications. Secondly, the use of a buffer fluid helps to cool and lubricate the seal faces, reducing wear and extending the life of the seal. Thirdly, tandem mechanical seals are easy to install and maintain, making them a cost-effective solution for many industrial applications.

Conclusion:

Tandem mechanical seals are an essential component in many industrial applications, providing an additional level of protection against leakage in high-pressure applications. They work by creating a barrier between the process fluid and the environment, using two sets of sealing faces arranged in series. The use of a buffer fluid helps to cool and lubricate the seal faces, reducing wear and extending the life of the seal. Tandem mechanical seals offer several advantages over other types of mechanical seals, making them a cost-effective solution for many industrial applications.