In many industrial systems, precise power transmission is vital for operational efficiency and reliability. The S5M circular arc pulley, commonly used with synchronous belts, plays a crucial role in ensuring smooth and accurate mechanical movement. Selecting the right pulley tailored to your specific industrial application can significantly enhance equipment performance and lifespan.

This article outlines the key considerations for choosing an S5M circular arc pulley and highlights Hetuoda Machinery Manufacturing, a trusted supplier specializing in high-precision transmission components.

What Is an S5M Circular Arc Pulley?

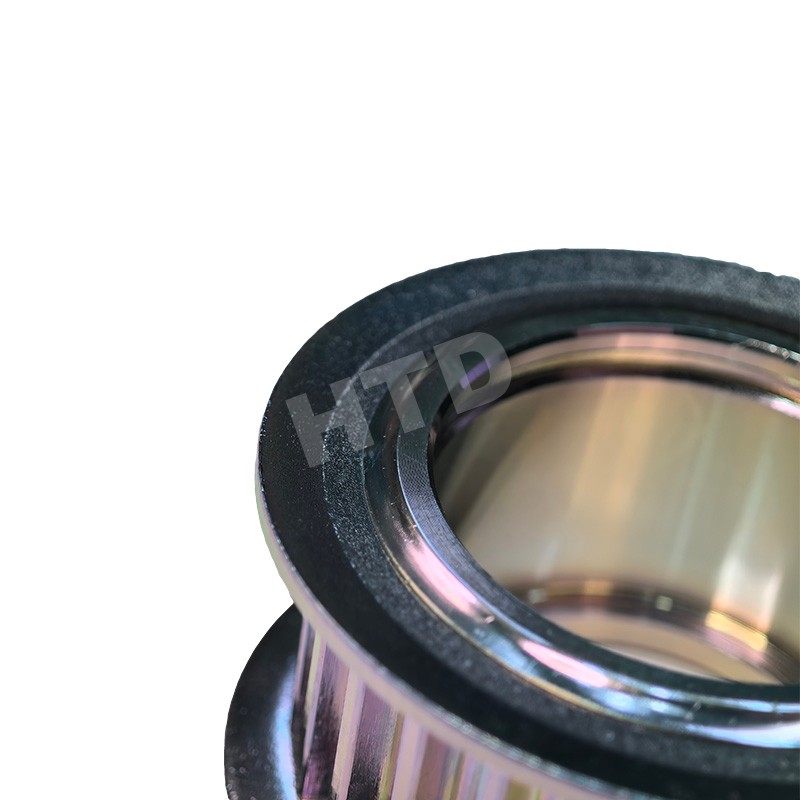

The S5M pulley is designed for synchronous belt drives with a 5mm pitch and features a circular arc tooth profile. This profile provides optimal belt engagement, reducing noise and wear while improving torque transmission and efficiency.

Circular arc pulleys are widely used in industries such as automation, robotics, packaging, printing, and textile machinery, where precision and durability are essential.

Key Factors to Consider When Choosing an S5M Circular Arc Pulley

1. Material and Durability

Select pulleys made from high-quality materials such as aluminum alloy, steel, or engineering plastics depending on load demands, environmental conditions, and corrosion resistance requirements.

2. Tooth Profile and Pitch

Ensure the pulley matches the belt’s tooth pitch—S5M pulleys have a 5mm pitch that must align precisely with synchronous belts to avoid slippage or premature wear.

3. Bore Size and Mounting

Consider the shaft diameter and how the pulley will be mounted. Custom bore sizes and keyway options can be important for a secure fit and easy installation.

4. Number of Teeth and Diameter

The pulley’s number of teeth affects the speed ratio and torque transmission. Selecting the correct diameter and tooth count ensures the right balance between speed and mechanical advantage.

5. OEM Customization

For specialized applications, customized pulleys with specific dimensions, materials, or surface treatments may be necessary to optimize performance.

Why Choose Hetuoda Machinery Manufacturing?

Hetuoda Machinery Manufacturing specializes in producing a wide range of high-precision transmission parts, including:

-

Synchronous pulleys (like S5M circular arc pulleys)

-

Rack gears

-

Tensioners (sets)

-

Gears

-

Various precision machined components

With advanced manufacturing processes and strict quality control, Hetuoda ensures that each pulley meets stringent standards for accuracy, durability, and performance. The company also offers OEM services, allowing customers to customize products according to unique application requirements.

Applications of S5M Circular Arc Pulleys

S5M pulleys are integral components in:

-

Automated assembly lines

-

Conveyor systems

-

Packaging machines

-

Textile and fabric machinery

-

Robotics and CNC equipment

Their precise tooth engagement and reliability help reduce maintenance costs and enhance operational uptime.

Conclusion

Choosing the right S5M circular arc pulley involves considering material quality, tooth pitch compatibility, bore size, and application-specific requirements. By partnering with an experienced manufacturer like Hetuoda Machinery Manufacturing, you can obtain high-quality, customized pulleys that ensure optimal transmission efficiency and long-term reliability.

Investing in the proper pulley not only improves machine performance but also reduces downtime and maintenance expenses, making it a smart decision for any industrial operation.

www.cdepulley.com

Suzhou Hetuoda Machinery Manufacturing Co., Ltd.