In the realm of medical devices and equipment, precision is not merely an advantage but a necessity. Medical grade precision mechanical parts play a crucial role in ensuring the accuracy, reliability, and safety of these devices. From intricate surgical instruments to sophisticated diagnostic tools, every component must meet the highest standards of quality and performance.

Key Selling Points of Medical Grade Precision Mechanical Parts

1. Unmatched Precision and Accuracy

Medical devices require an unparalleled level of precision, often measured in micrometers or even nanometers. SmartVein Medical Technology medical grade precision mechanical parts are manufactured using state-of-the-art CNC (Computer Numerical Control) machining and other advanced manufacturing techniques. This ensures that every part fits perfectly within its intended application, reducing the risk of malfunctions or errors during critical medical procedures.

2. Stringent Quality Control

Quality is paramount in the medical industry. SmartVein Medical Technology adhere to strict quality control protocols throughout the entire manufacturing process. From raw material selection to final assembly, each step is carefully monitored and inspected to ensure compliance with international medical standards such as ISO 13485 and ASTM. Our quality assurance team employs a combination of manual and automated testing methods to detect and rectify any defects before they become an issue.

3. Customizable Solutions

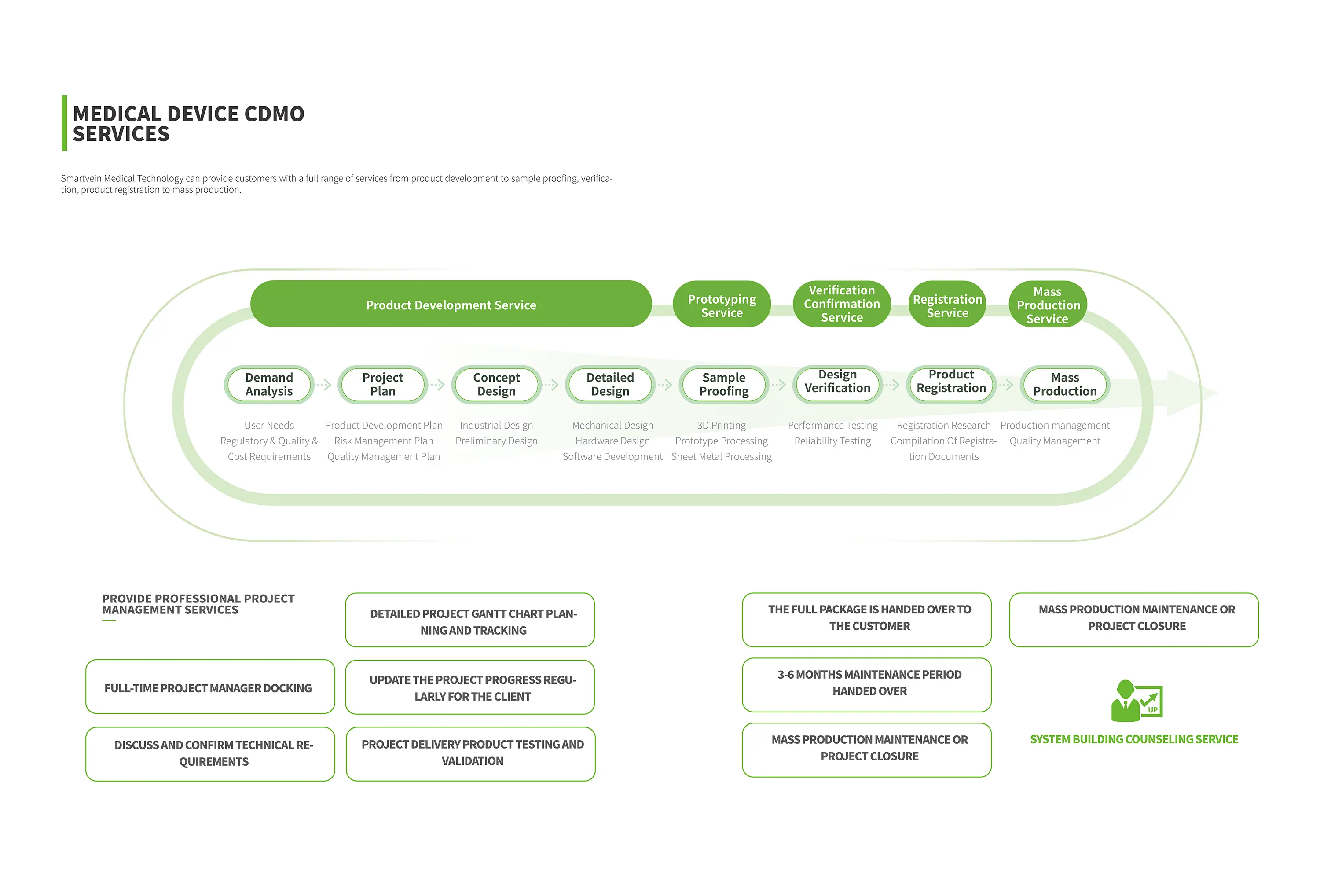

As an OEM, SmartVein Medical Technology specialize in providing customized solutions tailored to our clients' specific needs. Whether you require a unique part for a new medical device or an improvement on an existing design, we engineering team can develop a precision mechanical part that meets your exact specifications. This flexibility allows us to support a wide range of medical applications, from minimally invasive surgical tools to advanced imaging systems.

4. Regulatory Compliance

Medical devices are subject to rigorous regulatory scrutiny. SmartVein Medical Technology understand the importance of meeting all relevant regulatory requirements, including those set by the FDA, CE, and other global regulatory bodies. Our quality management system is designed to ensure compliance with these standards, from initial design through to final product release. This helps our clients navigate the complex regulatory landscape and bring their medical devices to market with confidence.

OEM Processing: Ensuring Quality Assurance

Advanced Manufacturing Capabilities

Our OEM processing capabilities are underpinned by a network of high-tech manufacturing facilities equipped with the latest machinery and technology. This includes precision lathes, milling machines, and multi-axis machining centers capable of producing parts with complex geometries and tight tolerances. Our skilled operators and engineers are trained to optimize these machines for maximum efficiency and accuracy, ensuring that every part meets or exceeds expectations.

Material Expertise

The choice of material is crucial in determining the performance and durability of medical grade precision mechanical parts. We offer a wide range of materials, including stainless steel, titanium, cobalt-chromium alloys, and advanced polymers. SmartVein Medical Technology material experts work closely with clients to select the optimal material for each application, balancing factors such as strength, corrosion resistance, and biocompatibility.

Comprehensive Testing and Validation

Before any part leaves our factory, it undergoes a rigorous series of tests and validations to ensure its fitness for purpose. This includes dimensional inspections, material testing, functional testing, and performance validation. We also conduct fatigue testing and stress analysis to assess the long-term durability of the parts under various conditions. By simulating real-world usage scenarios, we can identify potential failure points and make necessary adjustments to the design or manufacturing process.

Customer Support and Collaboration

SmartVein Medical Technology commitment to quality extends beyond the manufacturing process. We offer comprehensive customer support, including technical consultations, design reviews, and ongoing collaboration throughout the product lifecycle. This ensures that our clients receive not just a precision mechanical part, but a full-service solution that addresses their unique needs and challenges.

Conclusion

Medical grade precision mechanical parts are the backbone of modern medical devices and equipment. By leveraging advanced manufacturing capabilities, stringent quality control protocols, customizable solutions, and regulatory compliance expertise, SmartVein Medical Technology provide OEM processing quality assurance that ensures excellence in every part we produce. SmartVein Medical Technology commitment to precision, quality, and customer satisfaction makes us the ideal partner for medical device manufacturers seeking to bring innovative and reliable products to market.

www.smartveingroups.net

SmartVein Medical Technology