In recent years, 3D printing has revolutionized manufacturing processes across various industries. However, concerns about the environmental impact of traditional plastic-based 3D printing have led researchers and innovators to explore alternative materials and methods. In this article, we delve into the world of 3D printing without plastic, exploring sustainable alternatives that align with the growing demand for eco-friendly solutions.

- Bio-based Materials:

One promising avenue for 3D printing without plastic lies in the use of bio-based materials. These materials are derived from renewable resources such as plant-based polymers, algae, or even food waste. By harnessing the power of nature, bio-based materials offer a sustainable alternative to traditional plastics. Researchers have successfully developed bio-based filaments compatible with 3D printers, enabling the creation of intricate and durable objects. - Metal 3D Printing:

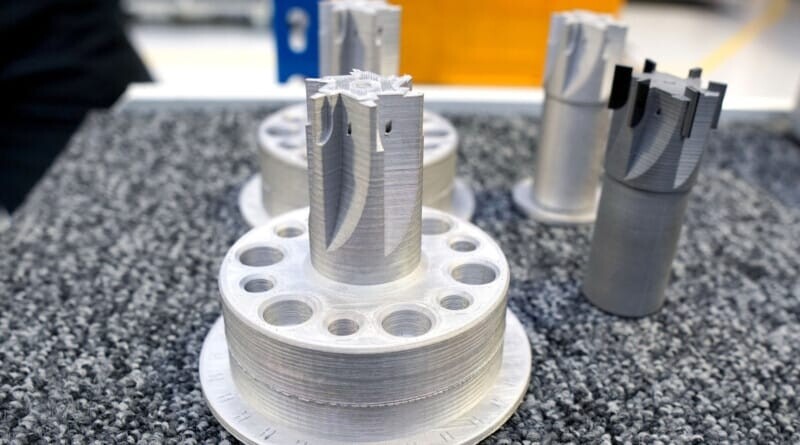

While plastic is commonly associated with 3D printing, it is important to note that the technology is not limited to this material. Metal 3D printing, also known as additive manufacturing, has gained significant traction in industries such as aerospace, automotive, and healthcare. By using metal powders, such as titanium or aluminum, and advanced printing techniques like selective laser melting or electron beam melting, intricate metal parts can be produced with high precision and strength. - Composite Materials:

Another approach to 3D printing without plastic involves the use of composite materials. Composites are formed by combining two or more materials with distinct properties to create a new material with enhanced characteristics. For instance, carbon fiber-reinforced composites offer excellent strength-to-weight ratios, making them ideal for applications requiring lightweight yet robust components. By utilizing composite filaments, 3D printers can produce parts that are both strong and environmentally friendly. - Sustainable Filament Recycling:

To further reduce the environmental impact of 3D printing, efforts are being made to develop efficient filament recycling systems. These systems aim to collect discarded prints, failed prototypes, and unused filament, and process them into new usable filaments. By implementing closed-loop recycling processes, the waste generated by 3D printing can be minimized, promoting a circular economy and reducing the reliance on virgin materials.

Conclusion:

As the demand for sustainable manufacturing practices continues to grow, the exploration of 3D printing without plastic has become increasingly important. Through the use of bio-based materials, metal 3D printing, composite materials, and sustainable filament recycling, we can pave the way for a more environmentally friendly future. By embracing these alternatives, we can harness the power of 3D printing while minimizing its impact on the planet.