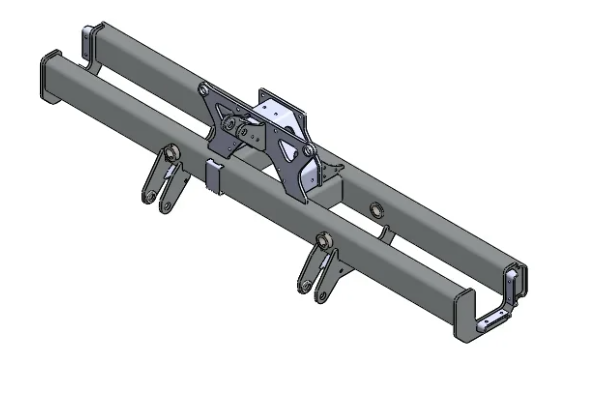

Choosing the right central beam for your projects is a critical step in ensuring structural integrity and project efficiency. At Hengli, we specialize in high-quality central beam processing services that include cutting, welding, bending, and machining. With over 200 skilled welders and 40 welding robots, our team ensures every central beam meets precise standards. Whether your project involves agricultural machinery, construction equipment, or industrial applications, understanding how to select the proper central beam is essential to success.

1. Understand Your Project Requirements

Before choosing a central beam, clearly define your project’s needs. Consider the type of equipment, load capacity, and operational environment. Hengli provides customized solutions based on detailed project drawings and specifications, allowing you to select a beam that matches both functional and safety requirements. Understanding the role of the central beam in your project ensures the structure will perform reliably under stress.

2. Consider Material and Strength

Central beams can be made from various materials, such as high-grade steel or aluminum alloys. The material impacts durability, weight, and resistance to environmental factors. Hengli’s central beams are fabricated from premium steel, offering high strength and excellent longevity. Choosing the correct material ensures your project withstands heavy loads and reduces maintenance over time.

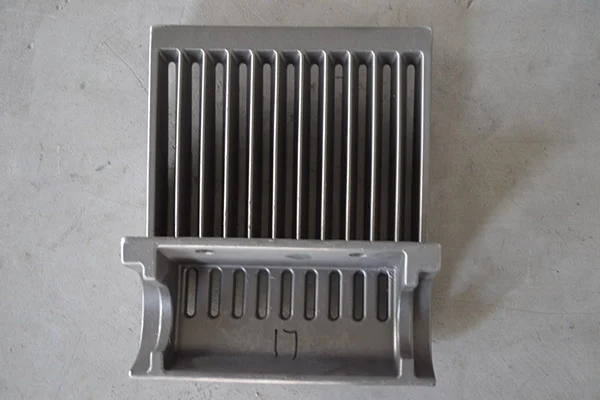

3. Evaluate Manufacturing Techniques

The production quality of a central beam depends on the manufacturing techniques used. Processes like laser cutting, plasma cutting, welding, and CNC machining influence precision and overall performance. Hengli combines mechanized welding with skilled craftsmanship to guarantee consistent quality. Paying attention to these processes helps prevent structural issues and ensures each beam fits perfectly into your project design.

4. Check Customization Options

Every project is unique, and sometimes standard central beams cannot meet specific requirements. Hengli offers tailored central beam solutions, allowing customization in length, thickness, welding patterns, and finishing. Collaborating with the manufacturer to adjust specifications can save time, reduce material waste, and ensure the beam meets exact functional requirements.

5. Assess Quality Control and Standards

Reliable central beam suppliers maintain strict quality control and adhere to industry standards. Hengli implements a comprehensive inspection process, from material selection to final finishing. Checking for certifications, testing protocols, and past project references helps you choose a supplier capable of delivering consistent, high-quality beams.

6. Consider Cost vs. Value

While price is always a factor, it’s important to balance cost with long-term value. Hengli provides competitive pricing without compromising quality, ensuring that your investment results in durable, efficient beams. Prioritizing value over initial cost can reduce repairs, downtime, and replacement expenses over the life of your project.

7. Plan for Installation and Maintenance

The right central beam should not only meet design and strength requirements but also be easy to install and maintain. Hengli’s central beams are engineered for straightforward integration into agricultural machinery, construction equipment, and other industrial applications. Proper installation and periodic maintenance maximize performance and extend the beam’s lifespan.

Conclusion

How to choose the right central beam for your projects comes down to understanding your requirements, selecting the proper material, evaluating manufacturing techniques, and considering customization and quality control. Hengli’s expertise in central beam processing ensures that each product delivers high performance, reliability, and long-term value. By working with a trusted supplier like Hengli, you can confidently select central beams that meet the demands of your projects while maintaining efficiency and safety.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.